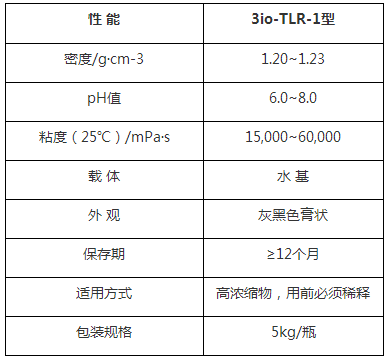

Product model: 3io-TLR-1

Product name: MoS2 water-based lubricant for hot forging

Specifications: 25Kg

Product use: MoS2 water-based lubricants for hot forging are mainly used in the fields of metal casting, die casting, stamping, forging and powder metallurgy manufacturing.

Product category: Molybdenum disulfide water-based lubricant

MoS2 water-based lubricant for hot forging is a high-concentration molybdenum disulfide water-based coating (release agent), which is made of ultra-fine molybdenum disulfide and adding a small amount of composite surfactant through high-tech methods. The filler is non-fluorine and non-silicone. It is smokeless, odorless, non-toxic and non-polluting when used. It meets environmental protection requirements. Mainly used in metal casting, die casting, stamping, forging and powder metallurgy manufacturing.

Physical properties

Features

1. Good mold release and lubricity, non-corrosive to the mold, and greatly prolong its service life.

2.Excellent separation surface, which has high-temperature lubrication for hot extrusion, hot forging and hot drawing.

3. The surface of the die-casting is not black, non-carbonized, bright and clean, and will not adversely affect the subsequent processing or painting.

Instructions for use

1. Mould preparation

The surface of the mold should be clean and dry without grease, fine particulate impurities, etc. If the surface of the metal mold is very smooth, it is recommended to sand the surface with fine sandpaper if possible to facilitate the adhesion of the coating.

2. Coating preparation

Before use, it must be diluted with purified water to a suitable consistency according to different coating methods. When adding water for dilution, it must be stirred with a vigorous mixer.

3. Process requirements

A. Spraying

① It is recommended to use a standard spraying device (Bink type 7 spray) (pressure about 0.30 ~ 0.40MPa).

② In order to obtain a uniform coating, continuous spraying is not suitable. Intermittent spraying should be adopted, and the spray distance from the mold surface is about 15 ~ 30cm.

③ The coating is diluted with water (coating: water = 1: 5 ~ 8) to a consistency that can form a coating with a thickness of about 24-25μm; the coating of the secondary layer should be sprayed after the upper coating is dried.

④ When spraying, the spray angle should be adjusted according to the actual situation, and the orderly movement of the spray should be controlled so that the coating can cover all the gaps and surfaces of the mold.

B, brushing

① Use a softer brush to brush the paint in a small motion to prevent the paint from following the brush's movement and causing displacement;

② The secondary coating should be done after the upper coating is completely dry.

C, dip coating

The operation of multiple dip coatings tends to peel the coating, so the coating should be adjusted to a suitable consistency during dip coating, and the required coating thickness can be achieved by one dip coating.